ASTM D3787

Ball Burst Strength Test

Bursting Strength of Textile

Learn how ASTM D3787 guides the ball burst test method for evaluating the bursting strength of textile materials, ensuring precision and quality control in textile applications.

ASTM D3787 - Ball Burst Test Method for Bursting Strength of Textile

Textile materials used in medical, apparel, or industrial applications often undergo extreme stresses during usage. One essential quality parameter is bursting strength, which reflects how well the fabric can resist pressure applied from a specific point. ASTM D3787, a standard developed by ASTM International, provides a clear and reliable ball burst test method for evaluating the ball burst strength of woven, knitted, or nonwoven fabrics. This article will explore how ASTM D3787 works, its significance, and how testing professionals can accurately follow it to ensure compliance and product durability.

What Is ASTM D3787?

ASTM D3787 is the Standard Test Method for Bursting Strength of Textiles—Constant-Rate-of-Traverse (CRT) Ball Burst Test. It is specifically designed for fabrics that exhibit high elongation, such as knitted or stretch materials. This method employs a CRT tensile tester equipped with a ball burst attachment, enabling it to simulate multidirectional stress conditions by pressing a spherical steel ball against the fabric until rupture.

This method is commonly used across industries—from medical devices and apparel to technical textiles—to evaluate product quality, especially when the product is expected to withstand inflation, point loading, or stretching during use.

Ball Burst Test Procedure

The ball burst test method as per ASTM D3787 involves a specific and controlled testing process:

1. Specimen Preparation:

Prepare circular or square textile specimens, typically 125 mm (5 in.) in diameter or length, ensuring no two specimens have the same warp and filling yarns. Avoid edges—cut specimens away from the selvage to eliminate bias from reinforced edges.

2. Clamping the Sample:

The sample is clamped in a ring clamp without tension. The fixture ensures the fabric is held firmly while allowing vertical movement during the test.

3. Applying the Load:

A polished steel ball (25.4 mm ± 0.005 mm in diameter) is mounted on the fixed clamp of the CRT machine. The ring clamp moves at a constant speed of 305 mm/min ± 13 mm/min, pushing the fabric against the ball until the textile fails by bursting.

4. Recording the Results:

The maximum force exerted before rupture is recorded as the ball burst strength of the specimen. Typically, results are reported in pounds-force (lbf) or Newtons (N) with a precision of 0.1 lbf.

This method mimics real-world stress conditions better than flat tensile tests, especially for textiles used in garments or upholstery where deformation is multidirectional.

Importance of Measuring the Bursting Strength of Textile

The bursting strength of textile materials is a critical quality attribute:

- For product safety: Ensures fabrics in protective wear or medical packaging don’t fail under pressure.

- For durability: Helps manufacturers select the right material grade for high-use products.

- For regulatory compliance: Supports quality assurance and acceptance testing protocols.

- For customer satisfaction: Prevents defects that could compromise performance or aesthetics.

By using ASTM D3787, manufacturers can confidently report textile integrity, particularly when shipping in bulk or exporting to markets with strict standards.

How to Conduct an Accurate ASTM D3787 Test

To follow the ASTM D3787 procedure correctly, you’ll need specialized equipment and testing conditions:

- Use a CRT-type tensile tester with a valid ball burst attachment.

- Ensure the ball and ring clamp meet ASTM’s specified dimensions.

- Condition all specimens in the standard atmosphere (21 ± 1°C and 65 ± 2% relative humidity).

- Take a minimum of five specimens per material sample for statistical reliability.

- Report any anomalies or ruptures not caused by the test setup to ensure valid results.

For best results, work with equipment that offers automation, data logging, and programmable speed controls.

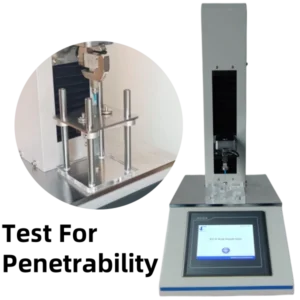

Puncturetest.com offers a precision Ball Burst Strength Tester fully compatible with ASTM D3787. Our instrument ensures:

High accuracy using a certified steel ball and ring assembly.

Automated clamping and loading for consistent results.

Real-time force-displacement curves and data export functions.

Customizable settings for different textile types and test requirements.

Backed by decades of experience in packaging, medical, textile, and pharmaceutical testing, Puncturetest.com is your trusted partner for reliable quality control solutions.