Needle Penetrability Tester and Its Role in Medical Testing

A جهاز اختبار نفاذ الإبرة plays a critical role in evaluating the mechanical interaction between needles and medical materials. In pharmaceutical and medical device industries, penetrability directly affects drug safety, injection performance, and packaging integrity. When a syringe needle pierces a rubber stopper or similar elastomeric material, the required penetration force must stay within a controlled range. Excessive force may cause needle deformation, coring, or user discomfort, while insufficient resistance can compromise sealing performance.

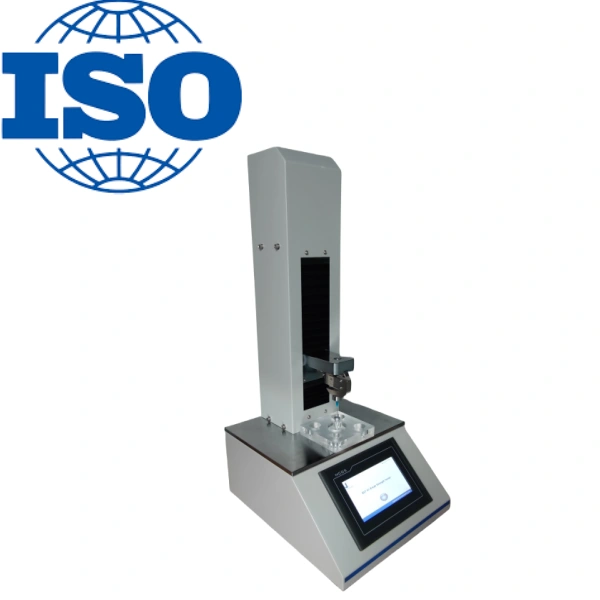

At Cell Instruments Co., Ltd, we focus on developing precise testing solutions that support manufacturers, laboratories, and quality inspection agencies in achieving consistent and compliant test results. The needle penetrability tester serves as a reliable tool to quantify penetration force and support data-driven quality decisions.

Penetrability Test for Rubber Stoppers in Pharmaceutical Packaging

إن penetrability test for rubber stoppers is a key quality control procedure in pharmaceutical packaging. Rubber stoppers are widely used in vials, infusion bottles, and prefilled systems. During drug administration, the stopper must allow smooth needle insertion while maintaining resealability and particulate safety.

This test measures the maximum force required for a needle to penetrate the stopper surface under controlled conditions. The result reflects material formulation, curing process, and surface treatment quality. By performing penetrability testing, manufacturers can:

- Ensure compatibility between rubber stoppers and syringe needles

- Reduce the risk of needle bending or coring

- Improve user experience during injection

- Maintain container closure integrity

International standards such as أيزو 7864 define requirements related to hypodermic needles, including mechanical performance aspects that strongly relate to penetration behavior. Aligning penetrability data with such standards improves regulatory acceptance and product credibility.

Syringe Needle Penetration Test and Force Measurement

A syringe needle penetration test evaluates how a needle interacts with elastomeric or polymer materials during insertion. This test focuses on penetration force, force curve stability, and repeatability. The measured force profile provides insight into material consistency and needle compatibility.

In practice, the test mounts a sample securely while the needle advances at a constant speed. The tester records force values continuously, generating accurate penetration curves. These curves help engineers identify abnormal peaks, surface defects, or formulation issues.

A well-designed needle penetrability tester ensures:

- Stable speed control

- High-resolution force sensing

- Repeatable test conditions

- Easy adaptation to different needle sizes

Such capabilities allow laboratories to perform routine quality control and R&D validation with confidence.

Hypodermic Needles Force Test and Standard

الامتثال

إن hypodermic needles force test extends beyond simple penetration. It examines how needle geometry, tip sharpness, and lubrication influence penetration behavior. This type of test supports compliance with أيزو 7864, which specifies performance requirements for sterile hypodermic needles.

By combining a needle penetrability tester with force analysis, manufacturers can:

- Compare different needle designs objectively

- Validate supplier consistency

- Optimize stopper formulations for specific needle types

- Support regulatory documentation with quantitative data

These tests strengthen overall quality systems and reduce risks during clinical use.

Testing Principles and Instrument Design Considerations

A professional needle penetrability tester uses precision load cells, rigid mechanical structures, and intelligent control systems. During testing, the needle moves vertically into the sample at a defined speed while force data is captured in real time. Clear force curves allow users to interpret penetration behavior accurately.

Important design considerations include:

- High force accuracy to detect small material differences

- Stable clamping systems to avoid sample deformation

- Flexible parameter settings for speed and penetration depth

- User-friendly interfaces for efficient operation

Cell Instruments integrates these principles into its testing solutions, ensuring long-term stability and reliable performance in laboratory environments.

Why Choose Cell Instruments Needle Penetrability Tester

Cell Instruments offers جهاز اختبار نفاذ الإبرة solutions designed for pharmaceutical and medical device testing. Our systems support customized fixtures, multiple needle specifications, and repeatable test protocols. With extensive experience in material testing instruments, we help customers improve testing efficiency while maintaining strict quality standards.

Our technical team supports customers from method development to routine quality control. By selecting Cell Instruments, users gain access to professional testing expertise, reliable instrumentation, and responsive technical support.

الخاتمة

A needle penetrability tester is an essential instrument for evaluating penetration behavior in medical materials. From the penetrability test for rubber stoppers to syringe needle penetration test and hypodermic needles force test aligned with ISO 7864, penetrability testing supports safety, performance, and compliance across the medical supply chain.

By implementing accurate and repeatable penetrability testing, manufacturers can enhance product reliability, reduce risks, and strengthen market confidence. Cell Instruments remains committed to providing advanced testing solutions that support innovation and quality in medical and pharmaceutical industries.