Dart impact test unit is an essential tool for evaluating the resistance of plastic films to impact forces. This test method, primarily used in packaging and material science, helps manufacturers ensure that plastic films can withstand impacts without failure during storage, transport, and usage. A key part of quality control, this test provides data that is critical for assessing the durability and integrity of plastic films used in various industries.

At Cell Instruments, we provide advanced testing solutions for materials like plastic films, adhesives, and textiles, helping manufacturers uphold the highest standards of quality. Our free falling dart impact testers are designed to offer precision and repeatability, ensuring reliable results for a range of plastic film applications.

Dart Drop Test for Plastic Film Resistance

One of the most commonly used tests in plastic film evaluation is the dart drop test. This test simulates real-world conditions by dropping a dart of specified weight from a defined height onto the plastic film. The dart impact test unit measures the energy required for the film to fail, typically noted when 50% of the specimens fail. By using standardized testing methods like ASTM D1709, manufacturers can determine the film’s ability to resist punctures and tears under pressure.

A dart drop test is particularly useful for assessing films used in packaging, as it mimics the stresses that the material may encounter during handling or transport. This test is crucial for products like food packaging, medical packaging, and industrial films, where film integrity is vital to the product’s safety and performance.

ASTM D1709 Test Method: Understanding the Standards

A ASTM D1709 standard outlines the procedure for testing the impact resistance of plastic films using a dart impact test. This method provides a structured approach to determine the weight of a dart that causes 50% of the specimens to fail. The test involves two variations, Method A and Method B:

- A módszer uses a 38.10 mm diameter hemispherical head dart dropped from 0.66 m.

- B módszer uses a larger 50.80 mm diameter dart dropped from a height of 1.52 m.

These tests help assess the film’s ability to resist impact without tearing or puncturing, which is crucial for industries where durability is essential.

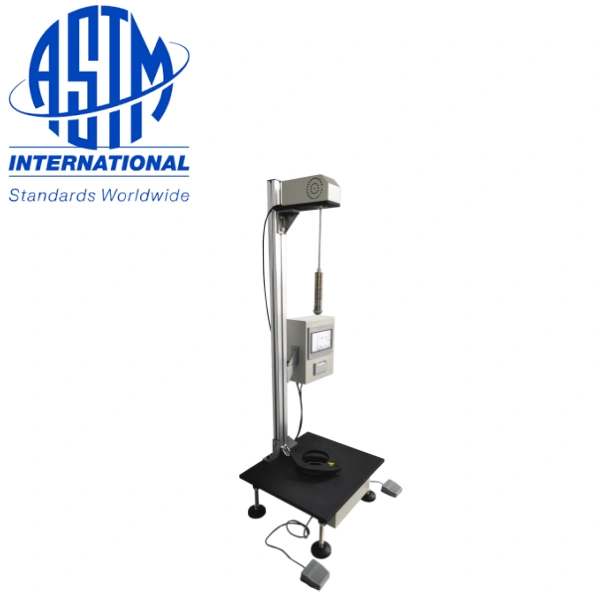

The Role of Free Falling Dart Impact Testers

A free falling dart impact tester is designed to perform these dart drop tests with precision. By measuring the failure point when a dart strikes the film, this testing equipment helps determine the film’s strength and toughness under impact conditions. Cell Instruments’ free falling dart impact testers are engineered to provide consistent and accurate results, ensuring that manufacturers can rely on the data to improve product quality.

A dart impact test unit, the dart is released from a specific height and strikes the plastic film with varying degrees of force, depending on the weight and drop height. The results of the test provide a clear understanding of the material’s performance and its resistance to failure.

Benefits of Dart Impact Testing for Plastic Films

Dart impact testing for plastic films offers numerous benefits to manufacturers, including:

- Improved Product Quality: Testing helps manufacturers ensure that their plastic films meet the required standards for impact resistance.

- Durability Assurance: Understanding the film’s performance in real-world conditions allows manufacturers to create more durable and reliable products.

- Compliance with Industry Standards: By following ASTM D1709, manufacturers ensure their products comply with global standards for packaging materials.

- Cost-Effectiveness: Identifying weak spots in the material before production helps reduce waste and improve overall material efficiency.

The Importance of Testing for Packaging Materials

Plastic films are widely used in packaging due to their versatility, but they must withstand mechanical stresses during production, transportation, and consumer use. The dart impact test unit is an indispensable tool for ensuring that packaging films can handle impacts without compromising the contents inside.

By integrating dart impact testing into their production processes, companies can improve the reliability and safety of their packaging materials, contributing to a better customer experience and stronger product integrity.

Conclusion: Ensuring Quality with the Dart Impact Test Unit

In conclusion, the dart impact test unit is a crucial piece of equipment for evaluating the resistance of plastic films to impact damage. Using ASTM D1709 and performing dart drop tests ensures that manufacturers meet industry standards for film strength and durability. By leveraging advanced testing technology, companies can enhance their mop quality assurance and ensure their packaging materials meet the required specifications for optimal performance.

At Cell Instruments, we provide robust and reliable testing solutions, including free falling dart impact testers, to help manufacturers achieve superior quality control in plastic film production. With our expertise and advanced equipment, we empower businesses to uphold high standards of material testing and product performance.