ISO 11040-4

Prueba de penetración con aguja

Garantizar el rendimiento y la seguridad de las jeringuillas precargadas es vital en las aplicaciones médicas y farmacéuticas. ISO 11040-4 esboza las especificaciones esenciales para barriles de vidrio para inyectables y jeringas subensambladas esterilizadas listas para el llenado. Una de las evaluaciones críticas de la calidad con arreglo a esta norma es la método de ensayo de penetración con agujaque evalúa la facilidad con que una aguja de jeringuilla penetra en un material estándar.

Qué es la norma ISO 11040-4 y por qué es importante

ISO 11040-4 es una norma mundialmente reconocida de la serie ISO 11040 que aborda específicamente barriles de vidrio para inyectables y jeringas esterilizadas premontadas destinados al llenado aséptico. Garantiza que estos componentes cumplan estrictos criterios dimensionales y funcionales para mantener la esterilidad del producto, la compatibilidad y la seguridad del paciente.

Una parte importante de esta norma es la prueba de penetración con agujaque verifica la rendimiento mecánico de la aguja durante su uso. La facilidad con la que una aguja puede perforar un sustrato se refleja en su nitidez, calidad del material, tratamiento de la superficiey la coherencia de la fabricación.

Estas pruebas son fundamentales para:

- Garantizar inyecciones suaves con mínimas molestias para el paciente

- Evitar que la aguja se rompa o se doble

- Garantizar la compatibilidad con los materiales de envasado

- Confirmación de la conformidad para la presentación reglamentaria

Explicación del método de ensayo de penetración con aguja

En método de ensayo de penetración con agujacomo se detalla en el anexo F de la norma ISO 11040-4, evalúa la fuerza necesaria para que la aguja de una jeringuilla perfore una lámina de ensayo definida. Este procedimiento se deriva de la norma DIN 13097-4 y está referenciado en ISO 7864Otra norma importante es la relativa a las agujas hipodérmicas estériles.

Los componentes clave del método incluyen:

- Aparato de ensayo: A probador universal de tracción y compresión con un rango de fuerza de hasta 10 N y una velocidad de 20-200 mm/min.

- Frecuencia de muestreo: Se recomiendan 500 Hz para una detección precisa de la fuerza máxima.

- Portaagujas: Asegura la alineación vertical para una penetración precisa.

- Lámina de prueba: El fabricante y el cliente acordarán el material y el grosor.

- Muestras de agujas: Puede estar siliconada o sin tratar, según el uso previsto.

- Recogida de datos: A curva fuerza/desplazamiento se genera para cada prueba, midiendo fuerza máxima y fuerza de resistencia.

El método garantiza que el afilado de la aguja y uniformidad del revestimiento están dentro de los parámetros aceptables, lo que garantiza un rendimiento fiable de la jeringa.

Prácticas recomendadas para la prueba con aguja de jeringa

Al realizar una prueba de la aguja de jeringuillaPor ello, es esencial seguir las directrices ISO y optimizar el proceso para garantizar la coherencia y la precisión:

- Utilizar sustratos validados: Tales como látex de caucho, poliuretanoo polietileno que imitan las condiciones de la piel o del envase.

- Controlar las variables medioambientales: Mantener la coherencia temperatura y humedad durante las pruebas.

- Evitar la reutilización de muestras: En cada prueba debe utilizarse una sección nueva de lámina o sustrato.

- Garantizar el calibrado: La máquina de ensayo debe calibrarse periódicamente con patrones trazables.

- Documentar a fondo: Incluya en el informe de ensayo las especificaciones de la lámina, la velocidad de ensayo, el número de muestras y todas las curvas de fuerza.

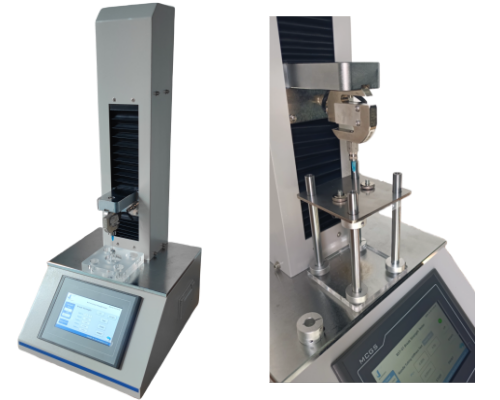

Para laboratorios y fabricantes que necesiten realizar pruebas de penetración de agujas conforme a la norma ISO 11040-4, Probador de penetración de aguja NPT-01 de Cell Instruments es una solución fiable y de alto rendimiento.

Principales características del NPT-01 incluyen:

- Sensores de fuerza de alta precisión con una exactitud de ±0,5%

- Velocidades de ensayo ajustables de 20 mm/min a 200 mm/min

- En tiempo real curvas fuerza-desplazamiento con datos exportables

- Portaagujas y pinzas para láminas personalizables

- Compatible con varios tamaños de jeringa y calibres de aguja

Utilización de la NPT-01 agiliza el cumplimiento de las normas ISO 11040-4 e ISO 7864, al tiempo que reduce la variabilidad y mejora la integridad de los datos. Es especialmente adecuado para Laboratorios de I+D, departamentos de control de calidady procesos de validación reglamentaria.