Introduction to Puncture Resistance Test

The puhkaisukestävyystesti is a critical evaluation tool for assessing the durability and protective capabilities of various materials, especially in applications where protection against sharp objects is essential. This test is commonly used in industries such as medical, protective clothing, and packaging. The ability of a material to resist punctures can indicate its overall strength, safety, and reliability, making it an essential parameter in product development and quality control.

At Cell Instruments, we provide advanced testing equipment that helps manufacturers evaluate materials with precision. Understanding puhkaisutesti pakkauksessa and its significance can enhance your ability to design and produce reliable, safe products that meet industry standards.

Puncture Test in Packaging: Why It Matters

When it comes to packaging, puncture resistance plays a vital role in determining the integrity and safety of the package during transport and handling. Packaging materials are often subjected to mechanical stress, and their ability to withstand punctures is crucial to preventing contamination, spillage, or damage to contents.

Puncture test in packaging allows manufacturers to evaluate the performance of materials such as films, bags, and containers. The puhkaisukestävyystesti is particularly useful for packaging solutions in the food, pharmaceutical, and medical sectors, where the safety and quality of products must remain intact throughout the supply chain.

This test is typically performed by using a needle or sharp object that applies force until the material penetrates. The puncture strength tester measures the force required to puncture the material, providing valuable data on its durability.

Puncture Resistance Test Procedure and ASTM F2878

The puhkaisukestävyystesti mukaan ASTM F2878-19 is designed to measure the resistance of protective clothing materials to punctures from hypodermic needles. The procedure involves using a standardized testing machine and needle to puncture a specimen under controlled conditions.

The general steps include:

- Näytteen valmistelu: A specimen of the material is prepared, ensuring it is free from wrinkles or tension.

- Neulan valinta: A hypodermic needle with defined specifications is used to puncture the material.

- Needle Penetration: The needle is moved at a constant speed until it penetrates the material.

- Force Measurement: The maximum force required to puncture the specimen is recorded using a load cell.

The ASTM F2878 test standard ensures that puncture resistance is evaluated under repeatable, consistent conditions, allowing manufacturers to compare different materials and products accurately.

Clothing Material Resistance Test: Evaluating Needle Puncture Resistance

The clothing material resistance test is crucial for evaluating the puncture resistance of various textiles, especially in industries like medical protective clothing, where safety is paramount. Protective garments such as gloves, aprons, and suits must be able to withstand punctures from sharp objects without compromising the protection provided to the wearer.

In this test, a needle is used to penetrate the material, and the maximum force required is recorded. The material’s ability to resist punctures is essential for ensuring that garments provide adequate protection against injuries or contamination.

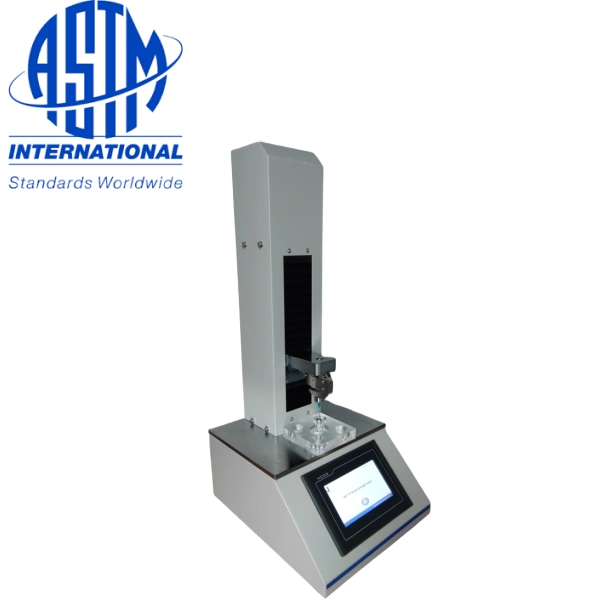

Needle Puncture Tester: A Reliable Tool for Accurate Testing

The neulan puhkaisu testaaja is an essential piece of equipment for conducting puncture resistance tests on materials. These testers provide precise measurements of the force required to puncture a sample, allowing manufacturers to assess the effectiveness of their materials.

Cell Instruments offers high-quality puncture strength testers that provide accurate and repeatable results. These testers can be used to evaluate a wide range of materials, including textiles, films, packaging, and protective clothing. Features of our testers include:

- Korkean tarkkuuden kuormitussolut for accurate force measurements.

- Adjustable speed settings to simulate real-world conditions.

- Customizable test parameters to suit different materials.

With these tools, manufacturers can ensure that their products meet the required puncture resistance standards and provide the necessary protection to end users.

Applications and Importance of Puncture Resistance Testing

Puncture resistance testing has far-reaching applications beyond protective clothing. It is also critical in assessing materials used for packaging, automotive components, and safety equipment. Some of the key industries that benefit from puncture resistance testing include:

- Medical: Ensuring the integrity of medical packaging, such as syringes and vials.

- Food: Verifying that packaging can withstand handling during transport and storage.

- Protective Wear: Evaluating fabrics and materials used in gloves, aprons, and suits for puncture resistance.

By testing the puncture resistance of materials, manufacturers can improve the durability and safety of their products, ensuring compliance with industry standards and enhancing customer satisfaction.

Conclusion: Enhancing Material Safety with Puncture Resistance Testing

In conclusion, puhkaisukestävyystesti is a vital part of ensuring that materials used in various industries meet safety and durability standards. Whether for protective clothing, medical packaging, or other applications, the ability to measure and improve puncture resistance can make a significant difference in product performance.

At Cell Instruments, we provide top-tier puncture strength testers that help manufacturers test and optimize their materials for the best possible performance. With accurate data and reliable testing methods, we support businesses in delivering products that exceed expectations and comply with industry standards.

For more information on our puncture testing equipment and how it can enhance your product development, contact Cell Instruments today.

Call to Action:

If you need precise puncture resistance testing solutions for your materials, explore Cell Instruments’ puncture strength testers. We offer customized solutions to help your business meet the highest quality standards. Contact us now for expert guidance!