ISO 12625-9

Ball Burst Strength Test

Puncture Testing Solution

Explore ISO 12625-9 for accurate tissue ball burst strength tests. Learn key procedures, standards, and instrument recommendations.

Introduction to ISO 12625-9 - Tissue Ball Burst Strength Test Method

The ISO 12625-9 standard outlines the method for determining the ball burst strength of tissue paper and related products. As tissue products are often lightweight and delicate, evaluating their puncture resistance is vital for quality assurance in applications like hygiene, food packaging, and medical supplies. This article explains the key components of ISO 12625-9, from sampling to test reporting, and guides professionals on how to conduct a compliant tissue ball burst strength test. It also recommends precision testing solutions, such as those offered by Puncturetest.com, to streamline and standardize the testing process.

ISO 12625-9:2015 is a critical part of the ISO 12625 series dedicated to tissue paper and tissue products. This part specifically focuses on determining ball burst strength—a measure of the force required to rupture a tissue sheet by a spherical probe moving at a constant speed.

The method is not only essential for assessing mechanical strength but also supports quality control and product development across industries such as personal care, foodservice, and medical packaging. A high ball burst strength indicates better durability and puncture resistance, crucial for performance during usage and transport.

Ball Burst Strength Test Procedure

The tissue ball burst strength test is often interchangeably called a ball burst test or puncture resistance test. Here’s a step-by-step breakdown of the process, following the ISO 12625-9 standard:

1. Principle of the Test

A stainless steel burst ball penetrates perpendicularly into a clamped test specimen at a controlled speed of 125 ± 5 mm/min. The maximum force recorded before the specimen ruptures is the bursting force, which quantifies the tissue’s resistance to puncture.

2. Sampling and Conditioning

- Use ISO 186 for selecting representative samples from a production lot.

- Condition the samples per ISO 187 in a standard atmosphere (23°C ± 1°C and 50% ± 2% RH) for accurate and reproducible results.

3. Preparation of Test Pieces

- Avoid creases, folds, or defects.

- Cut at least 10 test pieces, ensuring they exceed the clamping area.

- For multi-ply products, test them as received unless agreed otherwise.

- For perforated roll products like toilet tissue, use the center sheet of a 3-sheet segment for testing.

4. Test Execution

- Warm up the testing machine for at least 30 minutes.

- Clamp each test piece firmly but without tension.

- Begin the test with the burst ball pressing against the top side of the tissue.

- Measure the maximum force (F̄) in newtons as the ball ruptures the material.

- Repeat for all 10 test pieces.

5. Calculation

- Compute the average bursting force (F̄) and standard deviation.

- Calculate the burst index (X) using the formula:

X = F̄ / g

where g is the tissue grammage (g/m²).

6. Reporting

Include the following in the test report:

- ISO 12625-9 reference

- Sample details and sampling method

- Testing date, location, and conditioning atmosphere

- Mean and standard deviation of burst strength

- Burst index, if needed

- Clamping ring diameter

- Any test deviations or anomalies

Why the Ball Burst Strength Test Matters

Tissue products must balance softness and strength. A weak product risks rupture during production or use, while excessive strength may compromise comfort. The ball burst test bridges this quality gap by quantifying resistance in a standardized, reproducible manner.

For manufacturers, passing the ISO 12625-9 ball burst strength test builds trust with customers and regulatory agencies. For quality inspectors, it ensures product uniformity and compliance. For R&D teams, it aids in material formulation and performance optimization.

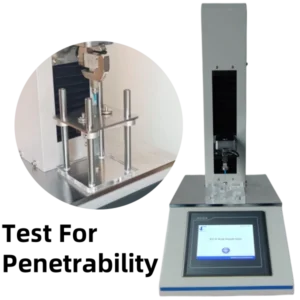

For reliable testing, a precision machine is indispensable. Puncturetest.com’s Tissue Ball Burst Strength Tester offers:

- Compliance with ISO 12625-9

- High-accuracy load cells

- Adjustable burst speed settings

- User-friendly interface and digital display

- Auto-calculation of average force and burst index

With robust construction and advanced data processing, Puncturetest.com ensures dependable results—ideal for production, quality control labs, and research environments.